Ardea

Inspired by the psychological concept of biophilia and the innovation method of biomimicry, Ardea aims to explore the conversion between nature, human psychology and science. The mission of this project was to create a vinegar pourer product under the constraints of the production process of slip casting. From research into the user experience of vinegar pouring and those available on the market, I wanted the geometry of the pourer to produce a controlled pour, specifically taking inspiration from geometry in nature. The end result is junction between biomimimetic and biophilic design generates a positive physiological effect on users, by reflecting a natural environment within increasingly disconnected domestic spaces.

Project type

Independent

Areas of work

Market research

Competitive analysis

Fluid dynamics testing

Ideation

Concept development

Prototyping

CNC

Slipcasting

Testing

Softwares

Rhino

Keyshot

Adobe Creative Suite

Timeline

February - April 2025

Materials

Earthenware

Cherrywood

Cork

RESEARCH

What’s up with vinegar pourers?

As an Italian and a life-long user of balsamic vinegar, this problem space was a long time coming. Balsamic vinegar is commonly used in and completes the flavour profile of many dishes. However, as a concentrated intensely-flavoured liquid, it has to be applied with precision, often a drizzle, as to not overpower the other flavours.

I wanted to investigate balsamic vinegar bottles and pourers on the market and evaluate the user experience of use; by measuring the amount of vinegar that pours out of the bottle at any given pour (size of the stream) and comparing the controllability of the pour (amount of splashing). I investigated and tested 6 different balsamic vinegar bottle types from 4 different stores to explore how the bottle shape effected the fluid dynamics and pour.

With the bottles I tested, there was often an uncontrolled pouring: ‘glug glug’ effect: Vinegar flows out creating a vacuum inside the bottle until the pressure difference is too high, then a bubble of air quickly rushes in to equalise the pressure through the same opening and the cycle repeats, causing bursts of liquid separated by air bubbles. This effect caused a lot of splashing as well as being very inconsistent and intermittent. Bottle with longer necks in ratio to their body size, had a reduced ‘glug glug effect, providing a smoother and slower pour.

This preferred form brought me to explore similar forms in nature, as a source of inspiration..

RESEARCH & DEFINING

Bird observation & photography

I explored bird life in my area, taking photos of all the above type of birds and comparing their different forms. What would happen if a vinegar pourer had an off-centred neck, relative to the bottle’s body, similar to bird form?

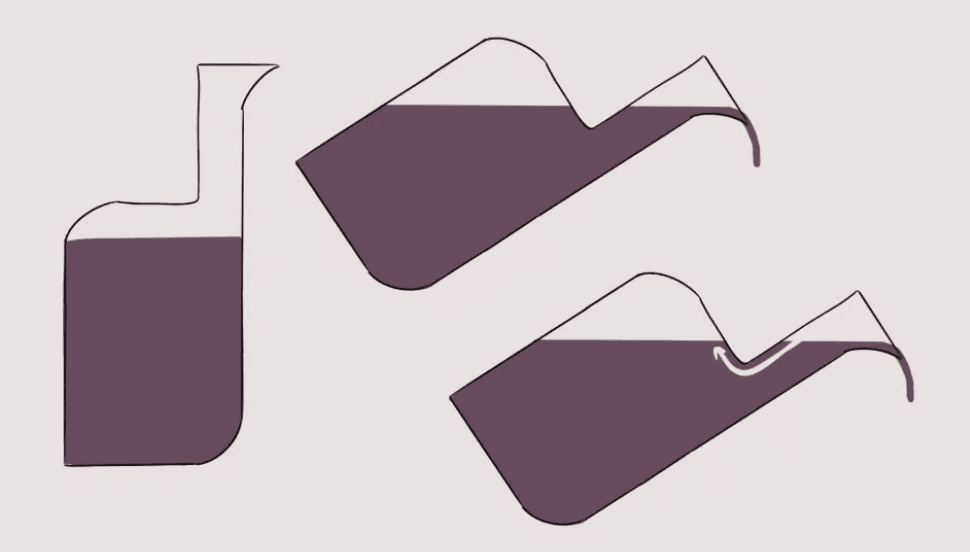

Hypothesis: An off-centre long spout might allow air to gradually slip in without disturbing the flow, leading to a more controlled and small pour with less of a “glug glug effect”.

IDEATION

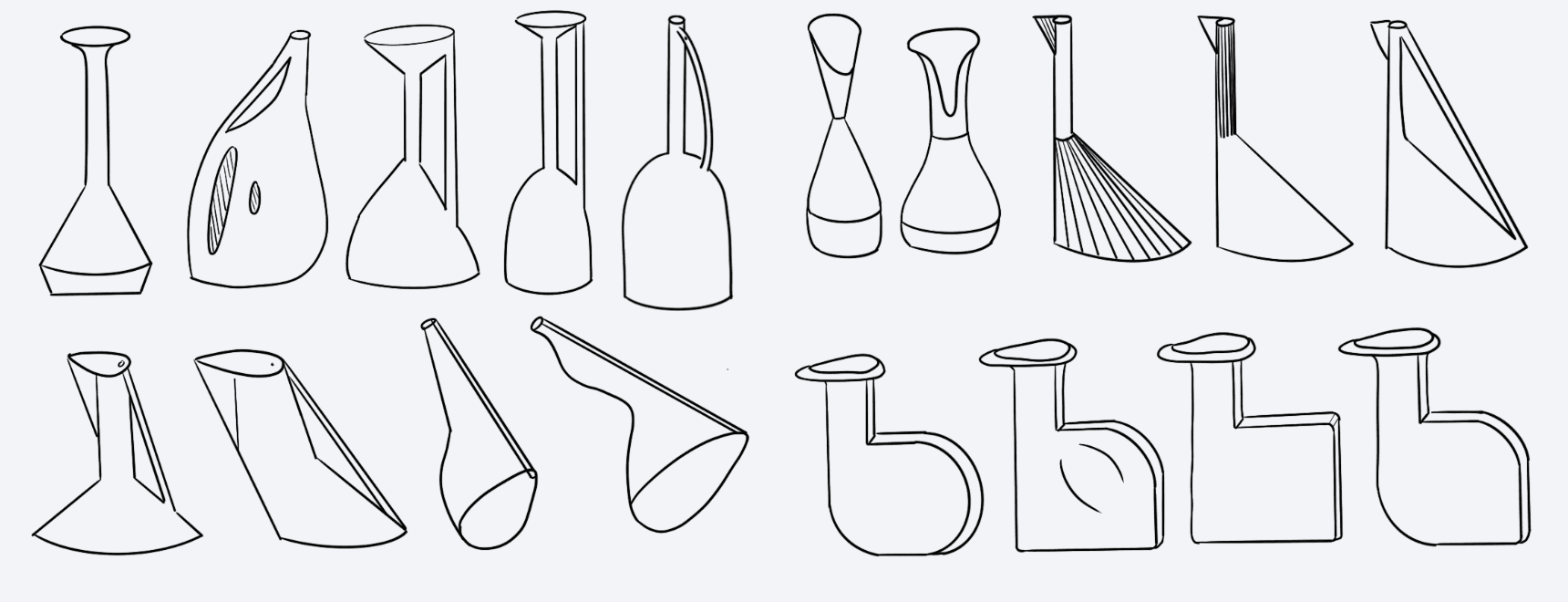

Concept development

Diagram of form testing

I chose this general form to develop further from my ideation, as it had this off-centred neck and a curved body where the user would hold, providing an ergonomic grip while maintaining visual resemblance to its natural inspiration. From testing in clay, the fluid dynamics functioned as predicted, approving my hypothesis. Due to the time constraints of this project, I couldn’t do further desired testing before going onto production.

CONCEPT DEVELOPMENT

Modelmaking

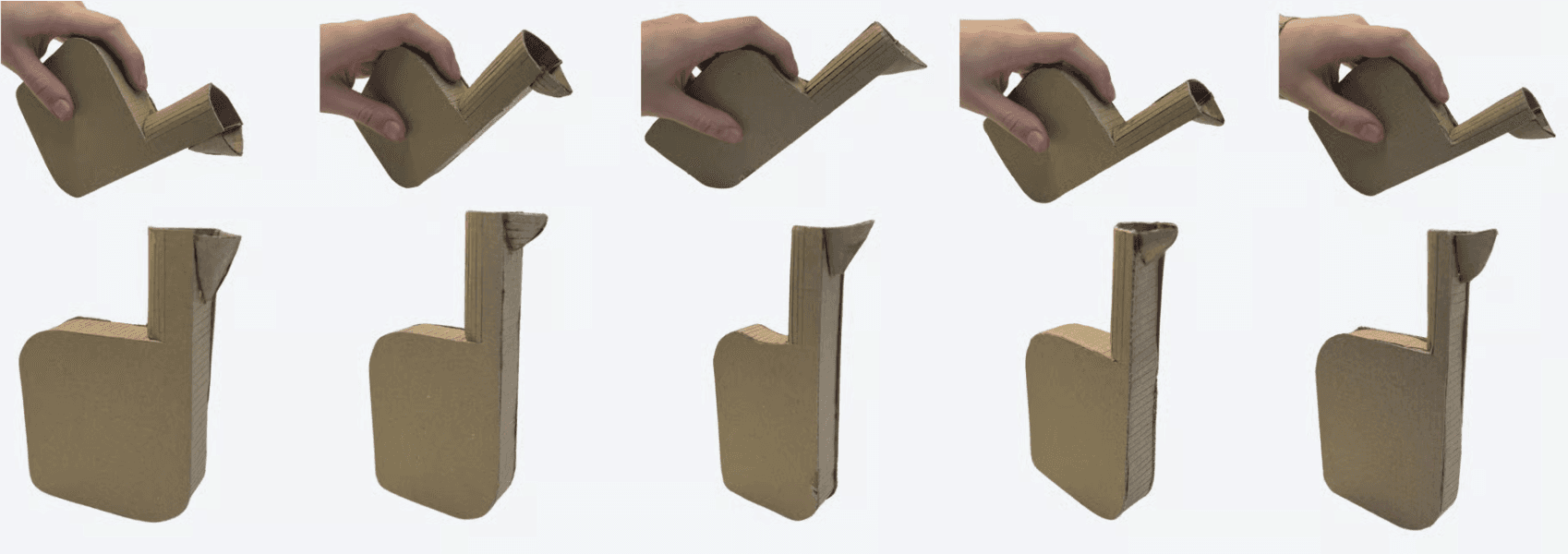

I made multiple cardboard models to test the ergonomic of each variation of the form. I moved forward with the model that had the best ergonomics in allowing a user to hold and pour, either from above the table, or while keeping contact between the table and the product.

DESIGNING

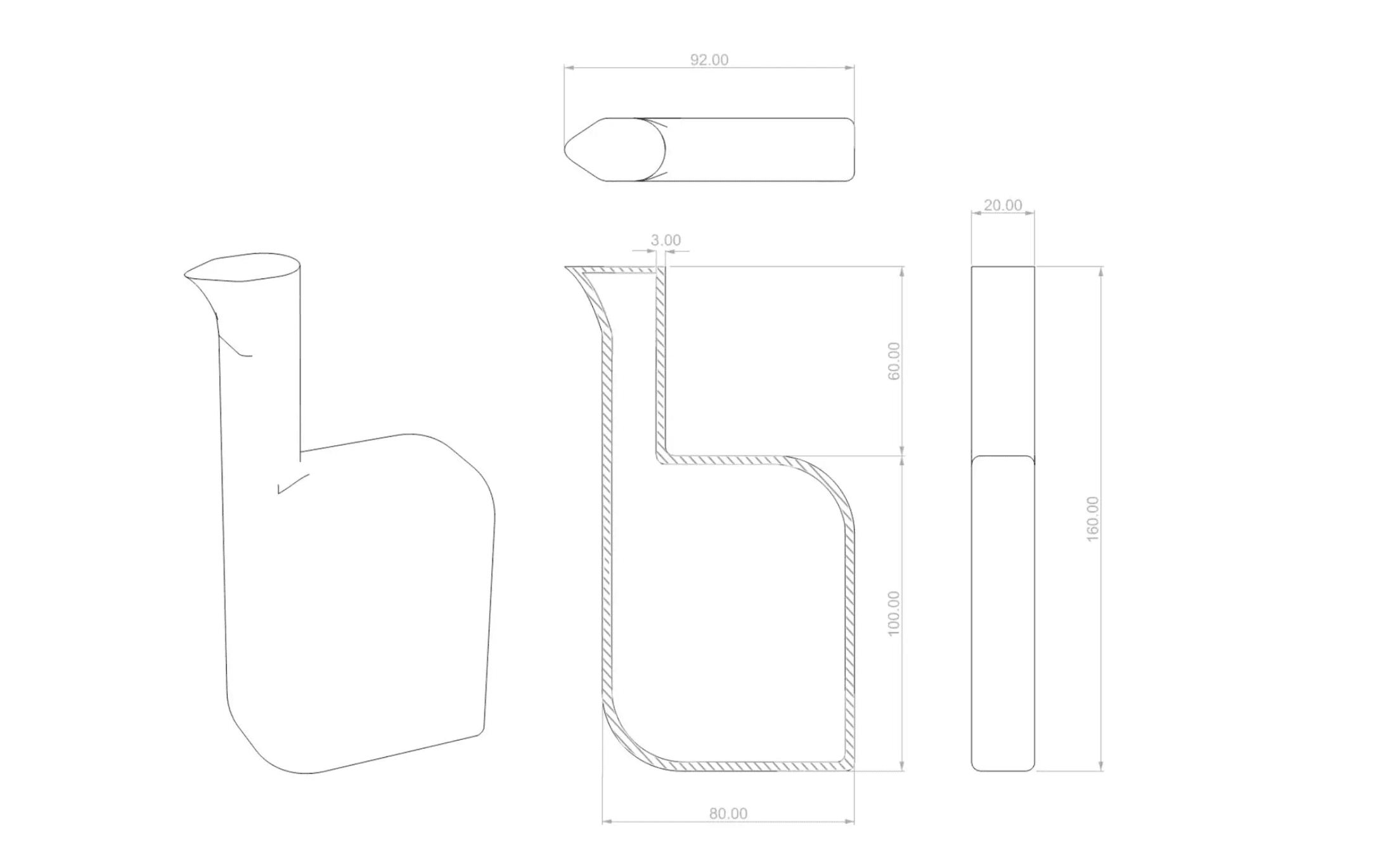

Technical Dimensions

MAKING

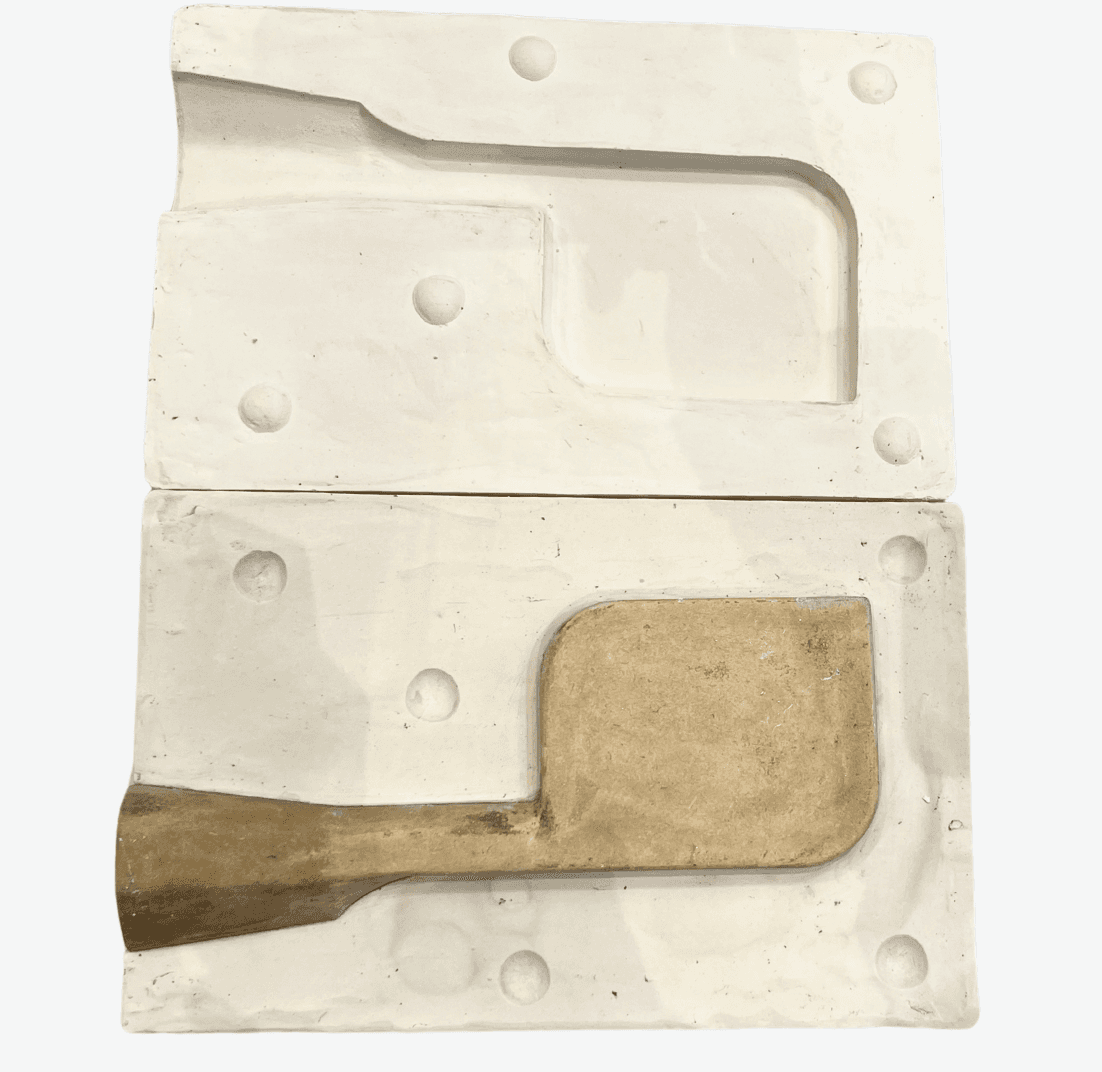

Case Mould

Process Overview

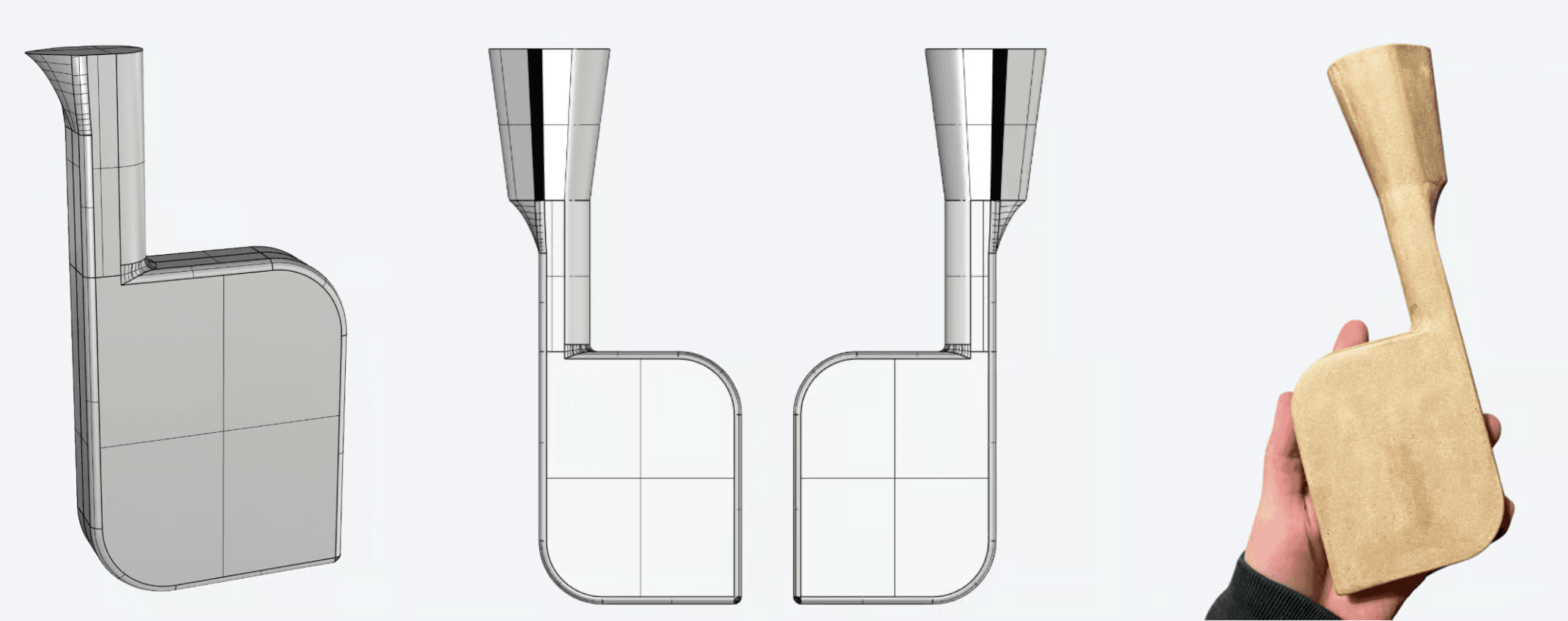

CAD model on Rhino (10% larger than technical dimensions - consider shrink rate)

Add a spare (for pouring of slip) onto the CAD model

Split the CAD Model in half for the CNC

CNC from MDF wood

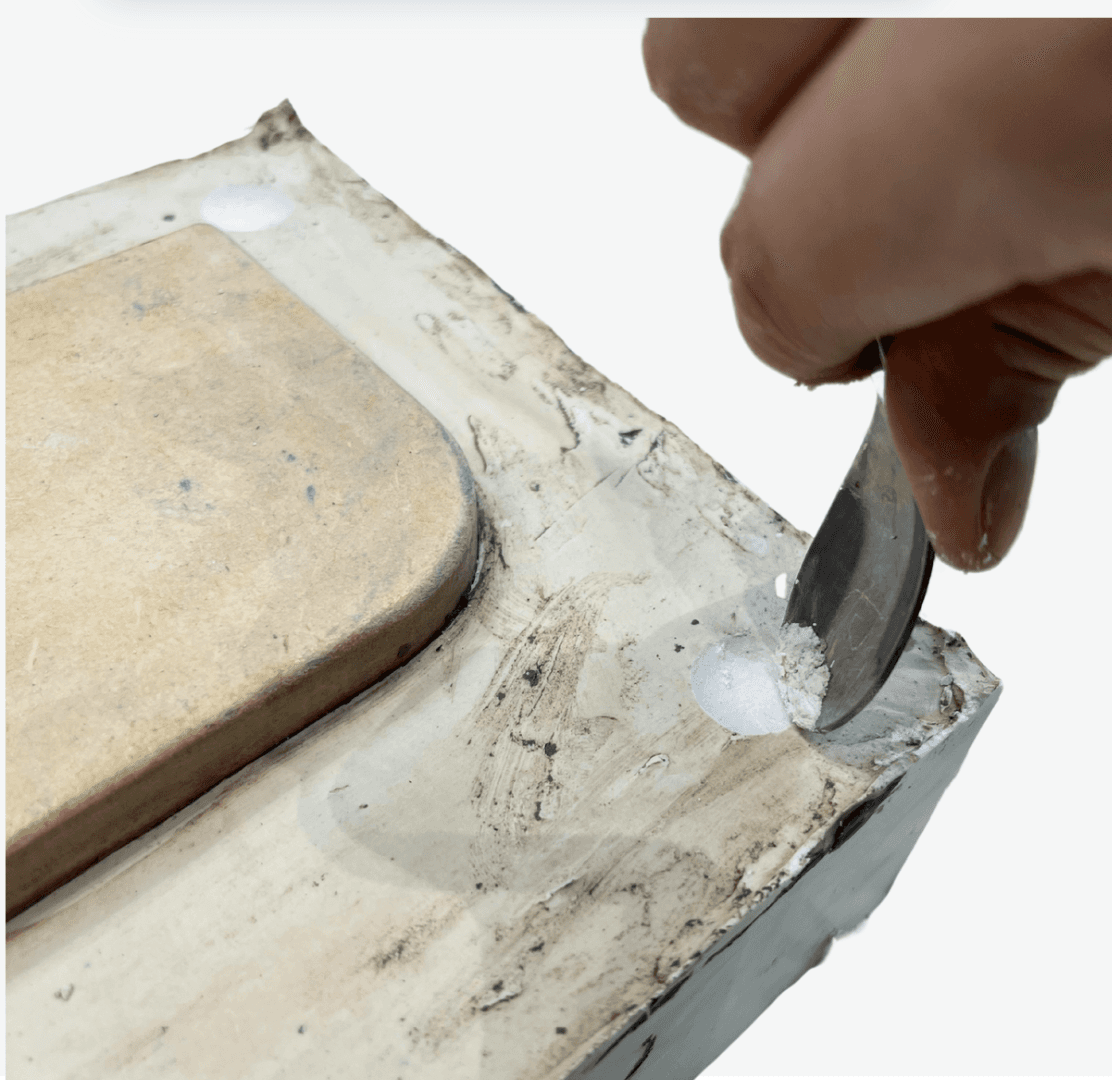

Glue, sand and seal

Get ready to make a plaster mould!

Making the plaster mould from the case mould

Slipcasting

Executing the production work myself, taught me a how much consideration must go into the design for production to be efficient. The consideration of the design could either make this process quick and easy or near impossible. The design itself and it’s complexity has a direct effect on how many parts are needed for the plaster mould. I created a two part mould. The more parts to a mould, the more money and time would be expended in the overall process.

CURIOUS?

Why earthenware? Why ceramic for balsamic vinegar?

I’m so glad you’re wondering... Traditionally, balsamic vinegar is tasted in ceramic “tasting-spoons”. Commonly today though, balsamic vinegar is stored in bottle of glass. However, ceramic vessels are still much preferred, when it comes to high quality vinegar, as they do not alter or compromise the vinegar’s complex flavour profile. Glass is beneficial for observing the vinegar’s colour and viscosity, however, ceramic is more-so ideal in maintaining taste as it prevents metal corrosion and preserves balsamic vinegar’s aromatics. For this purpose, and an ode to tradition, I wanted to create this product specifically from ceramic.

IDEATING & DESIGNING

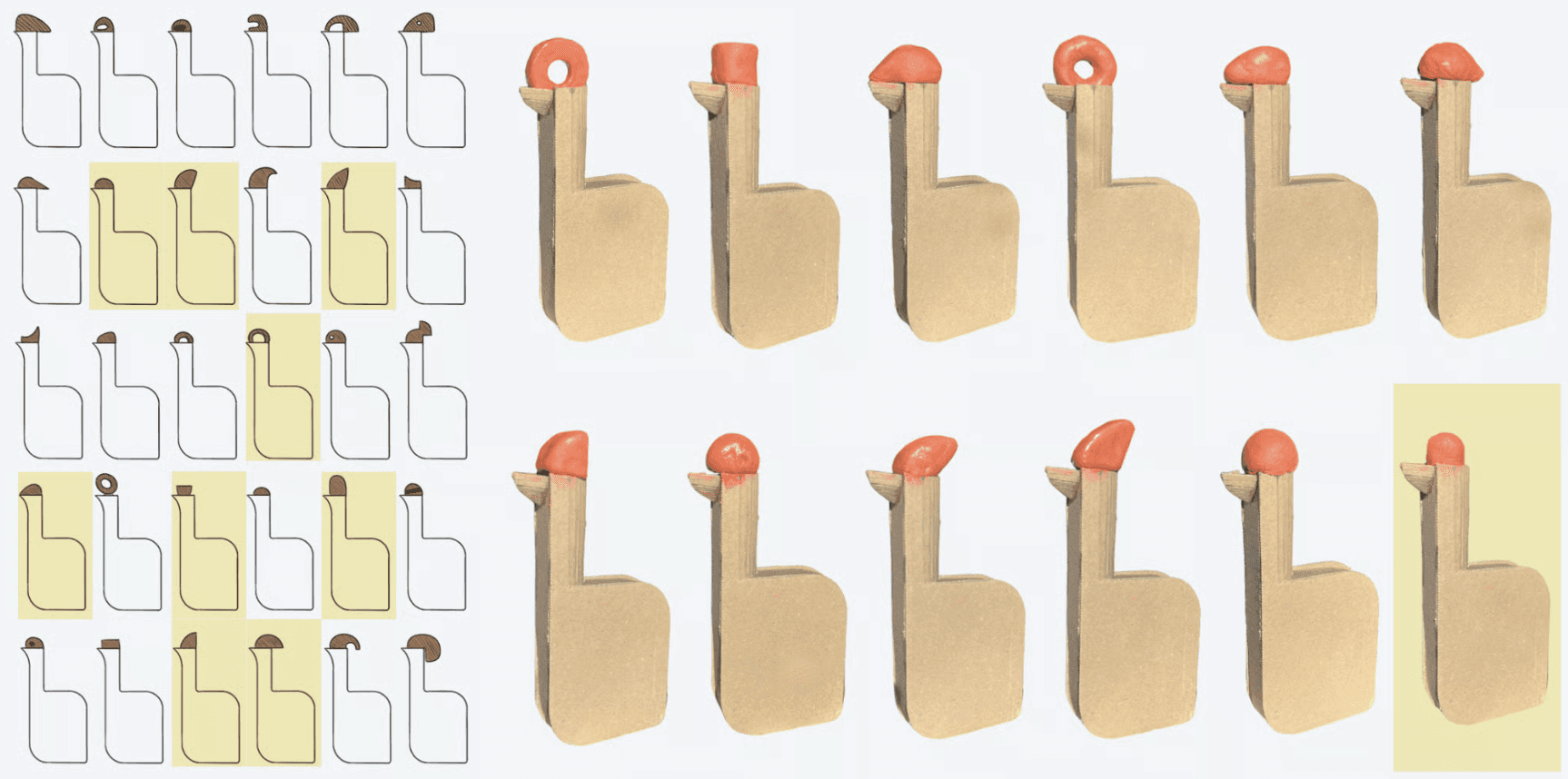

What about the bottle stop?

A lot of consideration went into the bottle stop, its shape and form; each bottle top model tested, created a unique personality. One that the user would associate with the product. I tested out different abstract and bird-head related shapes of different species. In the end I chose a more simplistic and general bottle stop shape, as to not anthropomorphise the product and to maintain production viability.

MAKING

Making the bottle stop

The bottle stop is made from joining of cherrywood and cork. The cork provides a seal in order to preserve the balsamic vinegar over time and the wood offers a durable and comfortable grip for repetitive use.

MAKING

Making the bottle stop

Inspired specifically by the form of the heron bird, Ardea, gets it’s name from the latin name of the genus of the heron bird. The form allows for pouring without having to lift the product off the table, resembling something similar to the pecking motion of birds. The shape and form of the vessel allows for a slow and smooth pour of vinegar, so that dispersion is consistent and controlled.